Some of our works

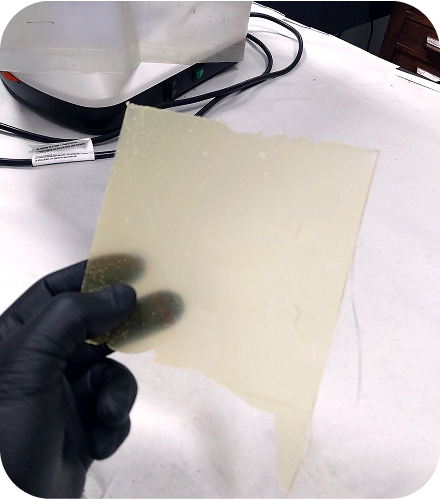

Biopolymer thin films development

We were commissioned to build thin films with a previous developed formulation. Those were performed with a polyurethane matrix made from a 100% biopolyol and common MDI isocyanate...

Open PDF

Vacuum infusion process layout design (CR Yachts)

In this occasion, CR Yachts, a Sweden yard with many years of experience on the sailing cruising yachts industry, required an improvement on his building process for hiw new 490 DS version, designed by BRYD...

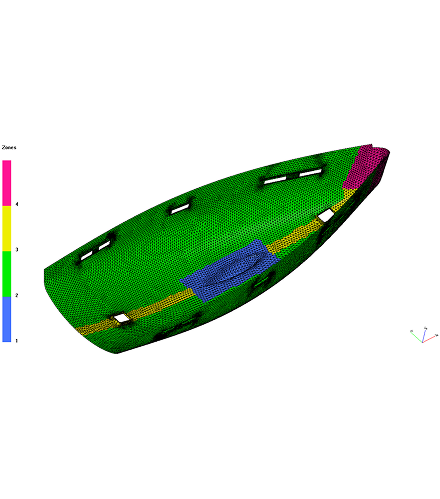

Open PDFHull and deck full structural analysis

We developed an advanced finite element model to deeply understand the hull and deck composites behavior of a 51 footer sailing boat that must reach the best quality standards.

Our reports

Kinetic and chemorheological modeling of thermosetting polyurethanes obtained from an epoxidized soybean oil polyol crosslinked with glycerin

Towards the development of a new matrix system, it is necessary to create cure kinetic and chemorheological models to deeply understand the curing behavior and the viscosity evolution against time of the resin involved in. In this occasion, Franco Armanasco participated on the development of a cure kinetic and chemorheological model of a soybean-based polyurethane system, in which different manufacturing processes can be predicted.

Download reportVacuum infusion process layout design (Antares Catamaran)

40 Grados Sur, a yard dedicated to build Antares Catamarans, came to us with the necessity on improving its composite manufacturing process. They used to apply hand-lay up manufacturing processes to build all its composites parts. COMMANTECH helped them start using VARTM (vacuum assisted resin transfer molding), better known as infusion. We designed the infusion layout process and obtained the required supplies to build the hull and the deck, as well as bulkheads and big parts.

Download reportThe role of post-cure cycle on the thermomechanical properties of soy-based polyurethane thermosets

In continuity on the research and development of the new biobased polyurethane system previously studied, Franco Armanasco participated on the characterization of the system in order to obtain its mechanical behavior by changing constituent in its formulation as well as its post-cure process. The results gave the research a boost to jump to a next step towards the development of new biobased resin systems.

Download report